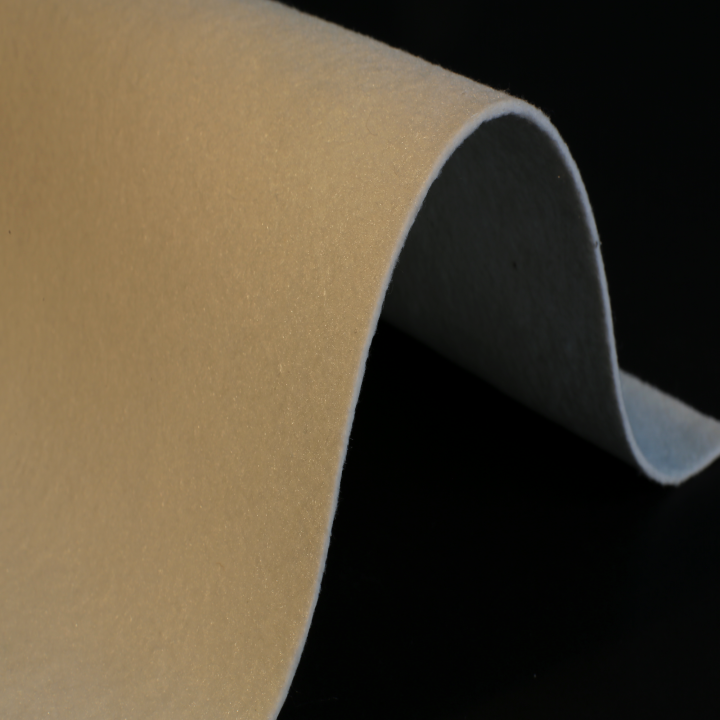

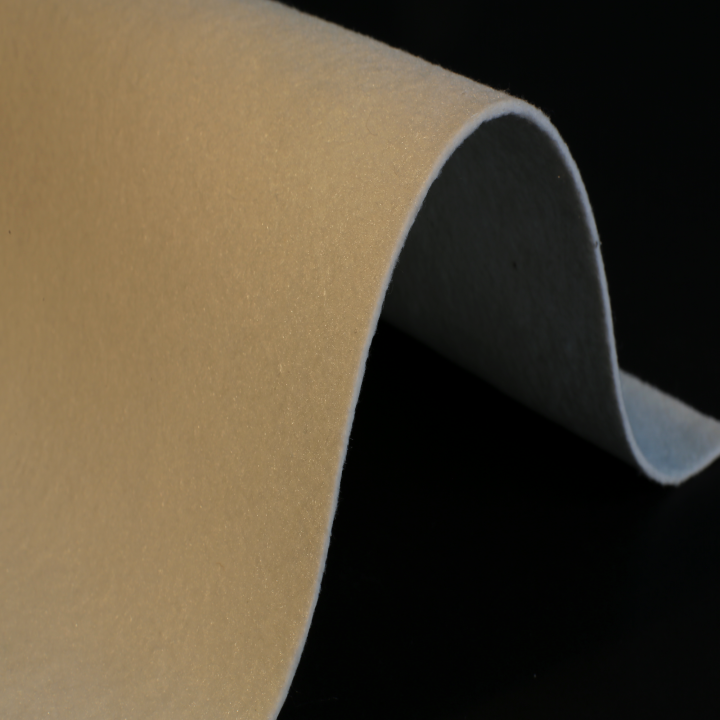

NEEDLE PUNCHED GEOTEXTILES

Polypropylene and polyester

Needle punched geotextiles are irreplaceable for ground stabilization, preventing material mixing as well as filtration and stabilization of the ground and the structure. The ones mostly used are polypropylene textiles (PP), as they are 2 to 6 times stronger than polyester geotextiles (PES).

Advantages

- Creating a barrier between individual layers of soil prevents them from mixing

- It ensures the stability and load-bearing capacity of the ground and structures

- Thanks to its hydraulic properties, it is used in drainage of ground structures

- It strengthens weak soil and stabilizes the substrate

Technical Data

| polypropylene | polyester | |

|---|---|---|

| Weight | 90-1200 g/m² | 100-1200 g/m² |

| Material | 100% polypropylene | 100% polyester |

| Tensile strength (EN ISO 103019) | 8-70 kN/m² ; 8,2-75 kN/m² | 1,3-11,8 kN/m² 1,9-12,7 kN/m² |

| Filtration opening (EN ISO 12956) | 110-70 μm | 50-40 μm |

| Dynamic perforation strength (EN 13433) | 28-0 mm | 28-0 mm |

| Length | min. 50 m, max 200 m | min. 50 m, max 200 m |

| Width | min. 1 m, max 6,2 m | min. 1 m, max 6,2 m |

For Download

1.02 MB |

pdf

ENG_GRILTEX_NEEDLE_PUNCHED_GEOTEXTILES

Roads and motorways

Roads and motorways  Railways

Railways  Waste and landfills

Waste and landfills  Mining

Mining  Parking lots and tree-lined roads

Parking lots and tree-lined roads  Sports and recreation

Sports and recreation